By default we use ASA from Polymaker

Warp-free ASA parts guaranteed

It is possible to request ASA from other brands, please contact directly.

Download TDS

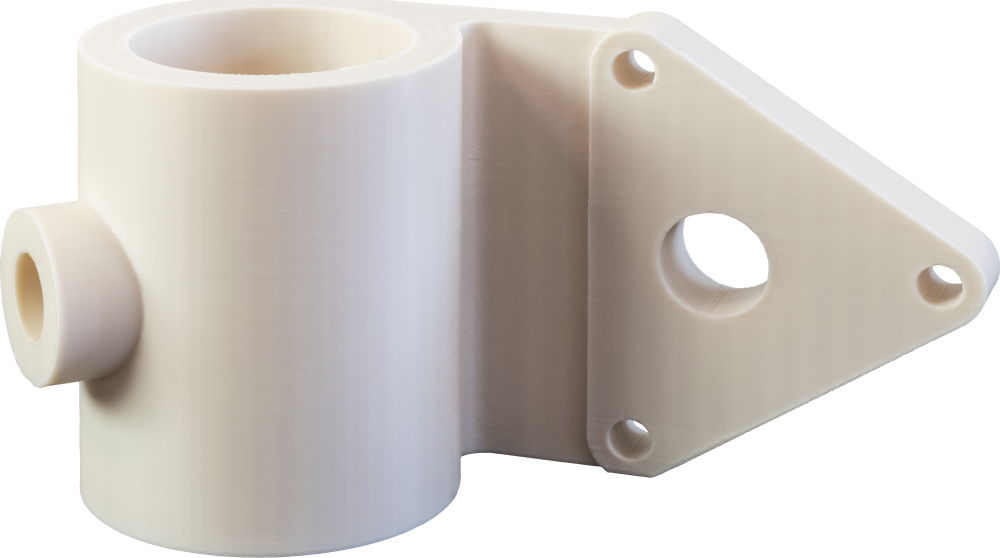

Model parameters and settings

- Bounding box: 86 x 70 x 22mm

- Infill: Medium (50%)

- Layer Height: 200 microns

- Weight: 25 grams

- Price if ordered one: 4.29 EUR

Available Colors

Custom colors from other brands are possible.

Pros and Cons of ASA

Pros

-

UV Resistant – Excellent outdoor durability; won’t yellow or degrade under sunlight.

-

Weather Resistant – Resists moisture, rain, and temperature fluctuations.

-

Strong & Rigid – Similar strength to ABS with better long-term stability.

-

Good Surface Finish – Smooth, matte appearance ideal for visible parts.

-

Chemical Resistant – Tolerates exposure to many oils and chemicals.

-

Easy Post-Processing – Supports sanding, painting, and gluing.

Cons

- Less Flexible Than Some Alternatives – Not suitable for high-flex applications.

- Limited Color Range Compared to PLA/PETG – ASA typically comes in fewer color options, especially for industrial-grade variants.

- Not Biodegradable or Eco-Friendly – ASA is petroleum-based and not a sustainable material choice.

- Slightly Brittle in Thin Sections – In very thin or narrow geometries, ASA can be prone to cracking or snapping.

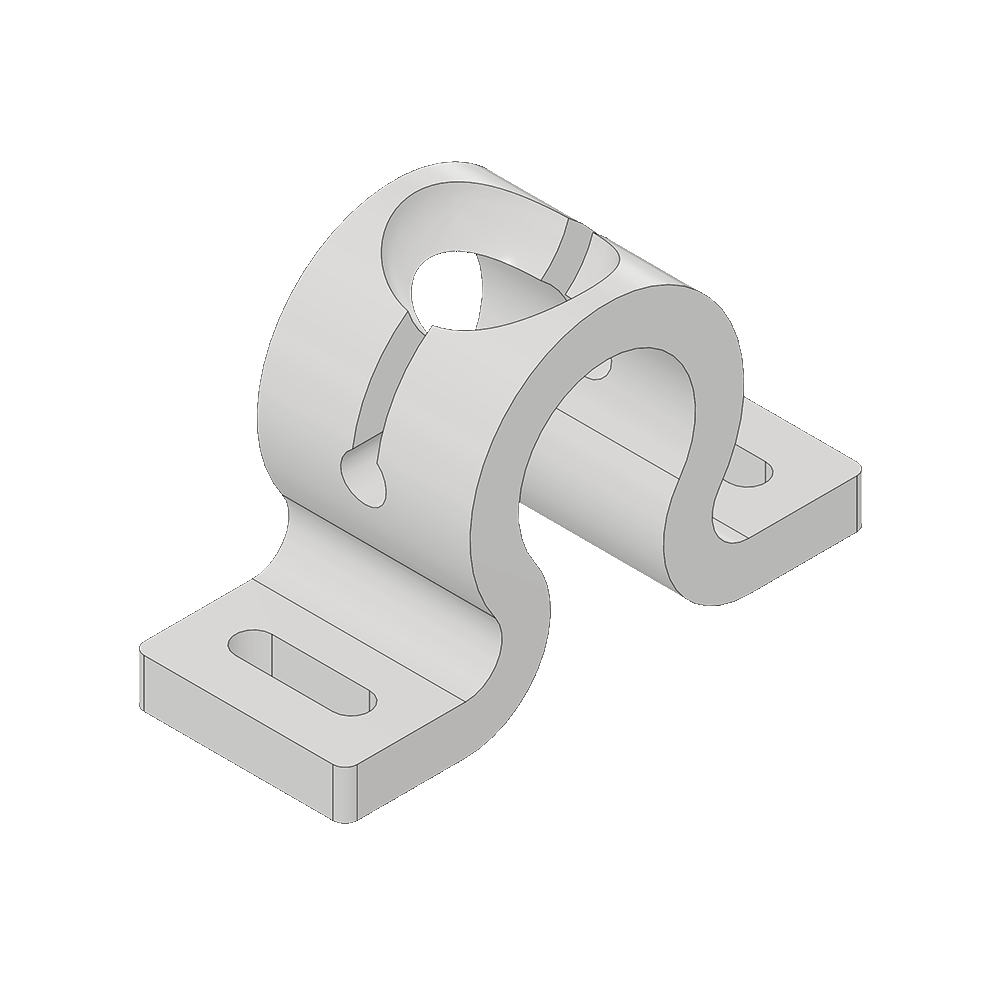

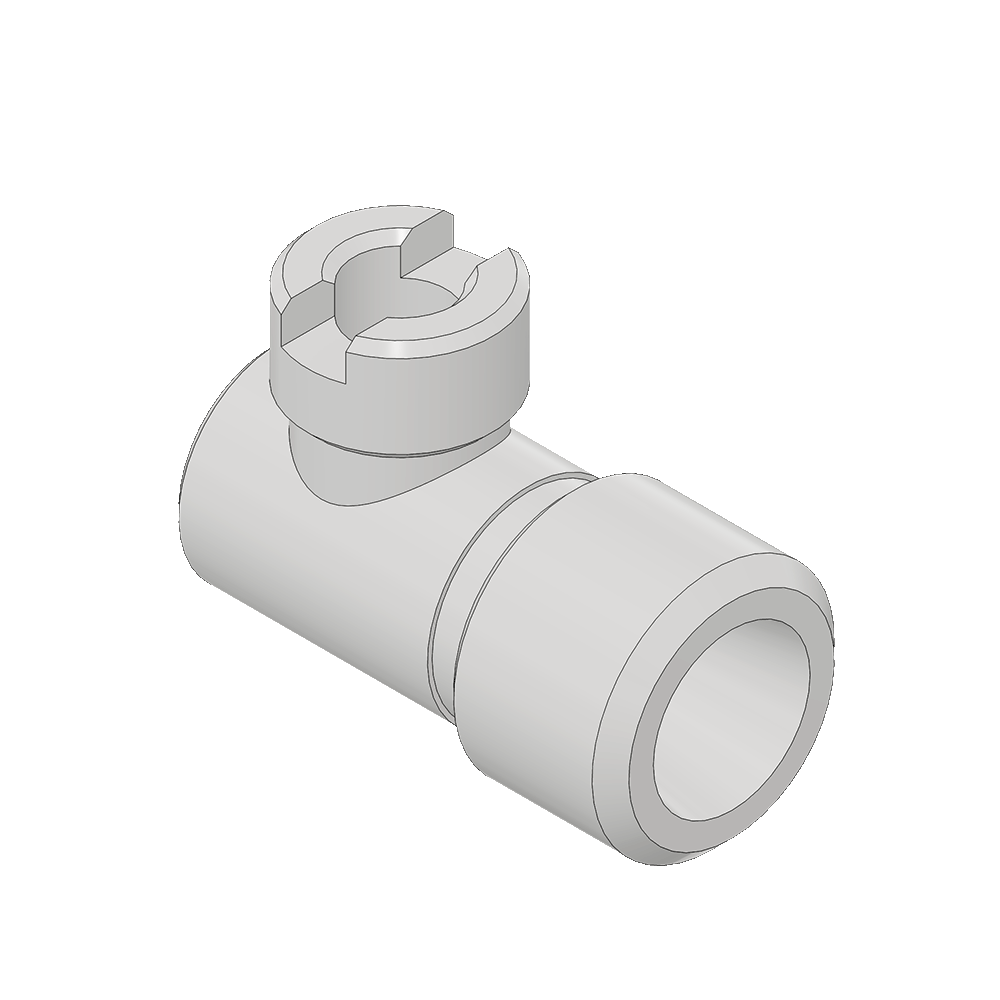

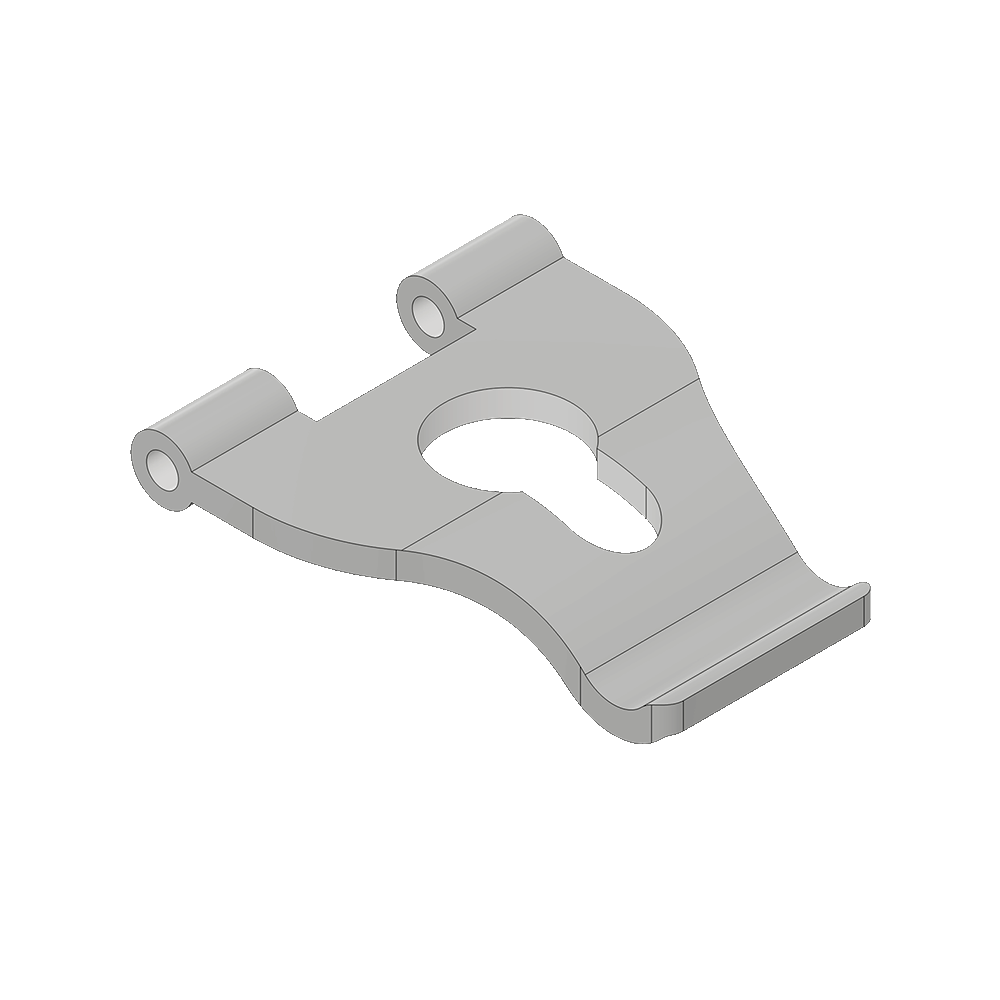

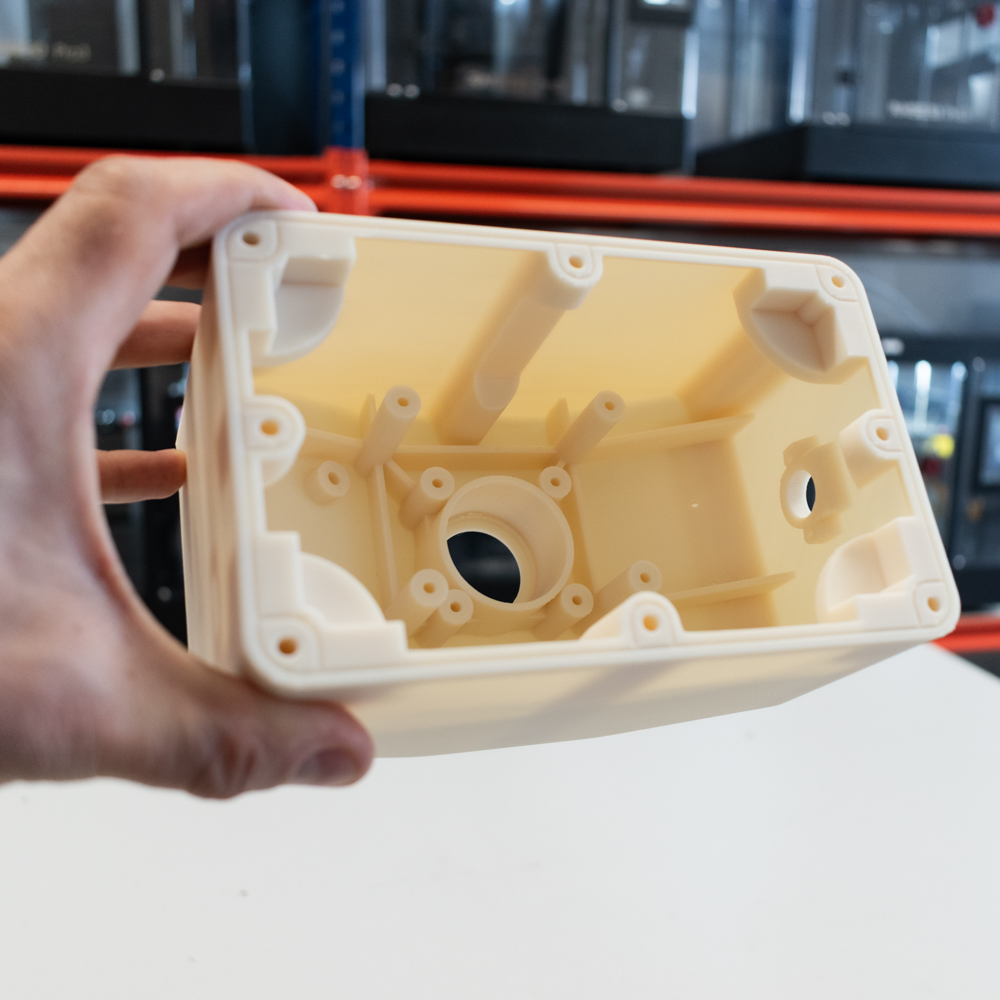

UV-Resistant Parts for Outdoor and Industrial Use

ASA (Acrylonitrile Styrene Acrylate) is a high-performance thermoplastic known for its excellent UV stability, weather resistance, and mechanical strength. It is an ideal material for functional prototypes and end-use parts exposed to outdoor conditions, making it a popular alternative to ABS in automotive, signage, electrical enclosures, and infrastructure applications.

Our 3D printing service uses industrial-grade ASA filament with FDM technology to produce durable, dimensionally stable components. ASA resists fading, cracking, and warping over time—perfect for parts that must endure sun, wind, and rain without compromising on quality.

Key Benefits of ASA

-

Excellent UV and weather resistance

-

High strength and impact durability

-

Superior surface finish and color stability

-

Ideal for outdoor or high-exposure environments

Our ASA Printing Service

All ASA parts are printed in-house with process control to ensure consistent quality and performance. Whether you’re producing outdoor fixtures, automotive trims, or rugged prototypes, we deliver results that meet industrial standards.

With over 30+ certified materials available on our platform, ASA stands out as the go-to choice for long-lasting performance in harsh environments. We support single prototypes to full-scale production with fast lead times and expert support.

ABS Material – Frequently Asked Questions

Need assistance or advice?

Contact us

Call us, visit, schedule appointment or simply schedule a quick video chat!

Contact usNeed material samples?

Get free samples!

Experience the quality firsthand—request your 3D printing material samples today.

Request samples