By default we use ABS from Polymaker

Warp-free ABS parts guaranteed

It is possible to request ABS from other brands, please contact directly.

Download TDS

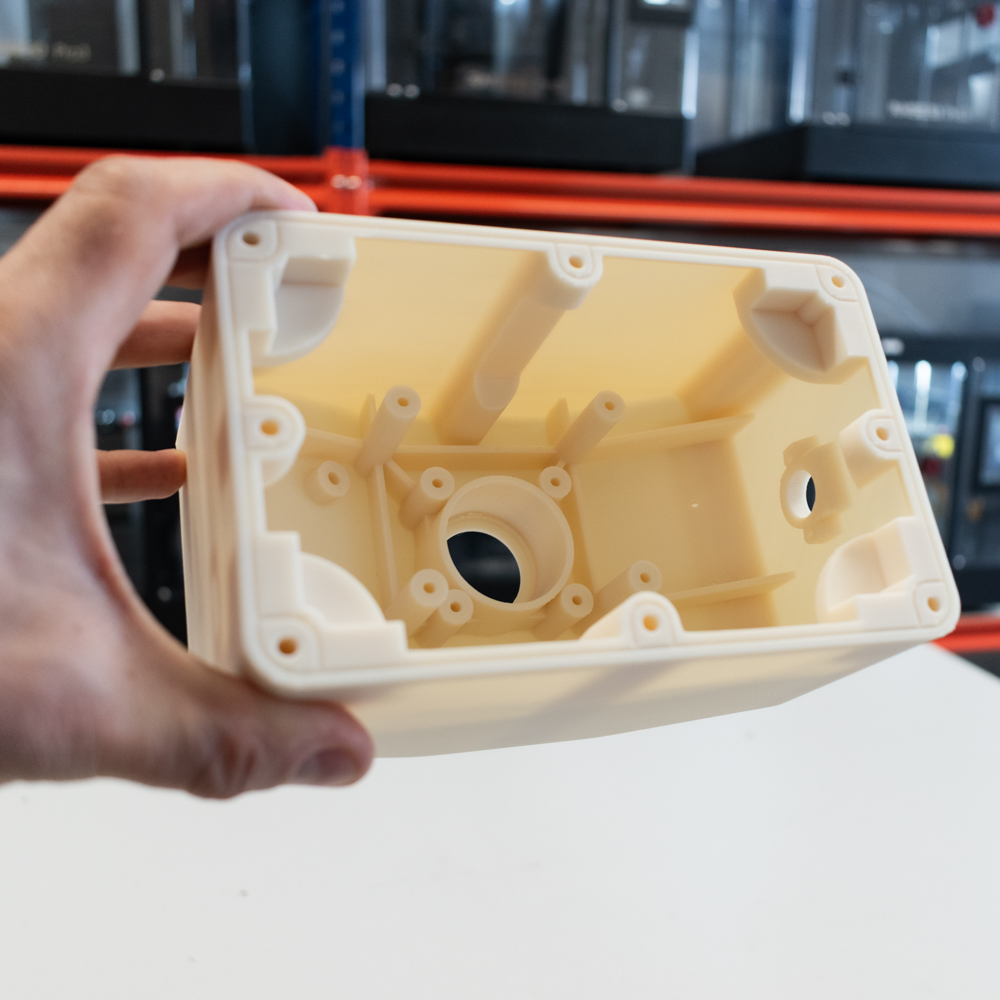

Model parameters and settings

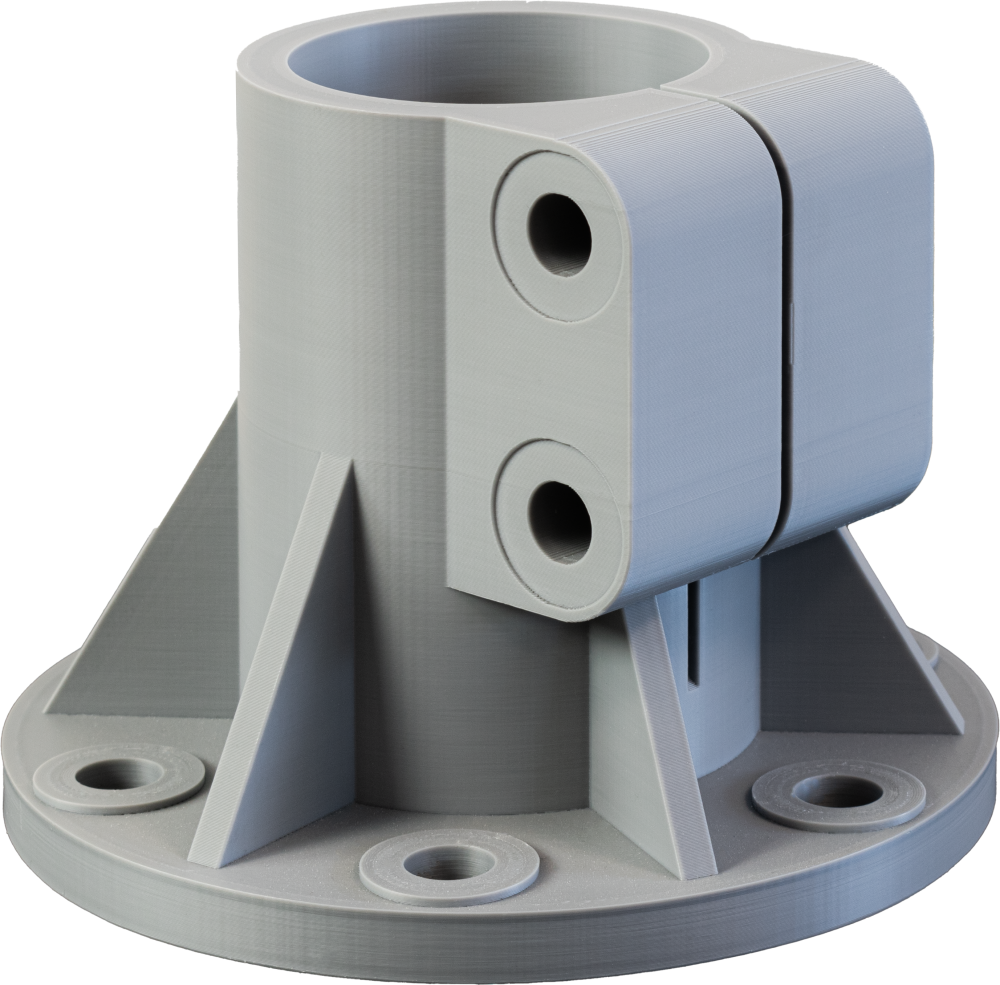

- Bounding box: 86 x 70 x 22mm

- Infill: Medium (50%)

- Layer Height: 200 microns

- Weight: 25 grams

- Price if ordered one: 4.06 EUR

Available Colors

Custom colors from other brands are possible.

Pros and Cons of ABS

Pros

- High Impact Resistance – ABS can withstand mechanical stress, making it ideal for parts that experience wear and tear.

- Excellent Dimensional Stability – Maintains accuracy in molded and printed parts under controlled conditions.

- Good Heat Resistance – Performs well up to ~100°C, suitable for enclosures, housings, and mechanical parts.

- Lightweight Yet Strong – Good strength-to-weight ratio, essential in automotive and aerospace components.

- Easy to Machine and Post-Process – Can be drilled, sanded, painted, and chemically smoothed—ideal for functional prototyping.

- Cost-Effective – Lower material cost compared to high-performance plastics, making it suitable for mass production.

Cons

- Limited UV Resistance –Degrades under prolonged exposure to sunlight unless stabilized (e.g., with UV additives).

- Not Suitable for High-Temperature Environments –Starts softening above 100°C—may deform in hot operational zones.

- Lower Chemical Resistance Than High-Performance Plastics –Not as robust as nylon, PEEK, or polycarbonate in chemically aggressive environments.

Why choose ABS?

ABS (Acrylonitrile Butadiene Styrene) is a trusted engineering thermoplastic used for strong, functional 3D printed parts. Known for its excellent impact strength, heat resistance, and mechanical durability, ABS is ideal for applications in automotive, consumer electronics, and manufacturing tools.

Our 3D printing service uses high-quality grade ABS filament with FDM technology to deliver precise, production-ready parts. ABS is perfect for printing jigs, fixtures, housings, enclosures, and functional prototypes that must withstand real-world conditions. It’s also post-process friendly—easy to sand, drill, or paint.

Why Choose ABS for 3D Printing?

-

High strength and durability

-

Good thermal resistance

-

Machinable and post-processable

-

Ideal for end-use and functional parts

Our ABS Printing Capabilities

We print all ABS parts in-house to ensure tight quality control, consistent material performance, and fast turnaround. Our experience in working with certified industrial materials makes us a trusted partner for companies in the automotive, electrical, and industrial sectors.

Whether you need a single prototype or a full production run, we deliver ABS components built to spec, on time, and with reliable performance.

ABS Material – Frequently Asked Questions

Need assistance or advice?

Contact us

Call us, visit, schedule appointment or simply schedule a quick video chat!

Contact usNeed material samples?

Get free samples!

Experience the quality firsthand—request your 3D printing material samples today.

Request samples