What is FDM 3D Printing?

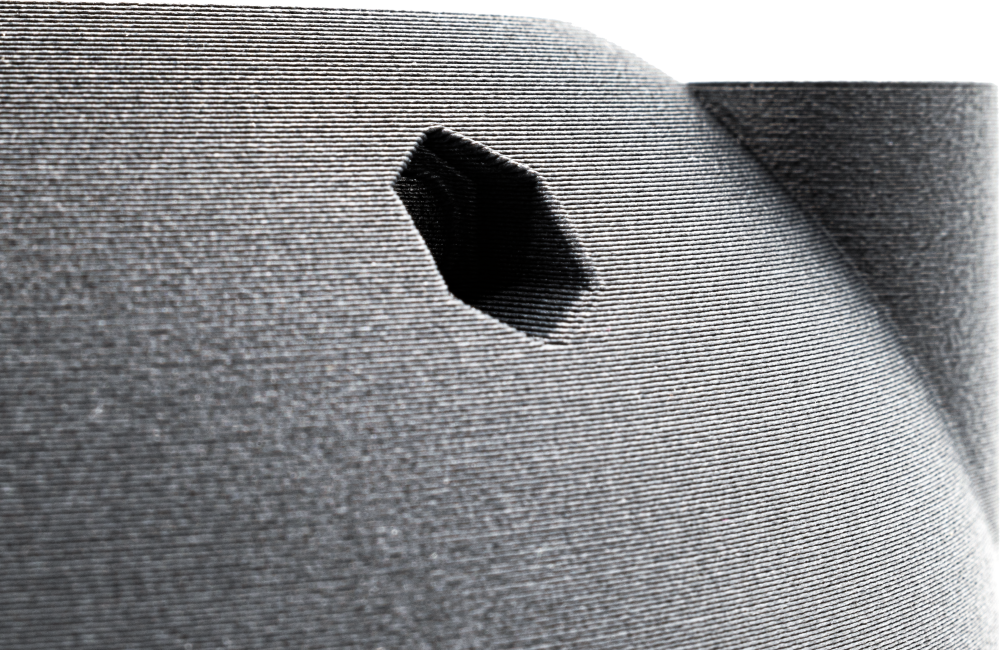

Fused Deposition Modeling (FDM) is a prominent 3D printing technology known for its simplicity and affordability. It operates by building objects layer by layer using thermoplastic materials. The process starts with a 3D digital model, typically created with CAD software, which is sliced into thin horizontal layers. These slices direct the printer as it extrudes melted filament through a heated nozzle onto a build platform. As the material cools, it solidifies, bonding with previous layers to form the final 3D object.

FDM technology supports a broad range of materials, each offering distinct properties. Commonly used materials include Acrylonitrile Butadiene Styrene (ABS) and Polylactic Acid (PLA). However, more advanced materials like Acrylonitrile Styrene Acrylate (ASA) provide enhanced UV resistance, making them ideal for outdoor applications. Polycarbonate (PC) is chosen for its high impact resistance and strength, suitable for engineering applications. Thermoplastic Polyurethane (TPU) offers flexibility and elasticity, perfect for producing soft, durable items.

The key advantages of FDM include cost-effectiveness, ease of use, and versatility in materials, which make it attractive to both hobbyists and industrial users. FDM is particularly useful for rapid prototyping, enabling quick design iterations without significant expense. Additionally, it’s applied in small-batch manufacturing for sectors such as automotive, aerospace, and healthcare.

FDM’s widespread use is bolstered by a large community that provides extensive resources and support, ensuring its continued popularity. Despite some limitations in resolution compared to other 3D printing methods, FDM remains a staple technology in the industry for its practicality, adaptability, and, most importantly, lowest price per piece across all 3D printing technologies.