How Orientation Affects Costs of 3D Printed Parts with FDM Technology

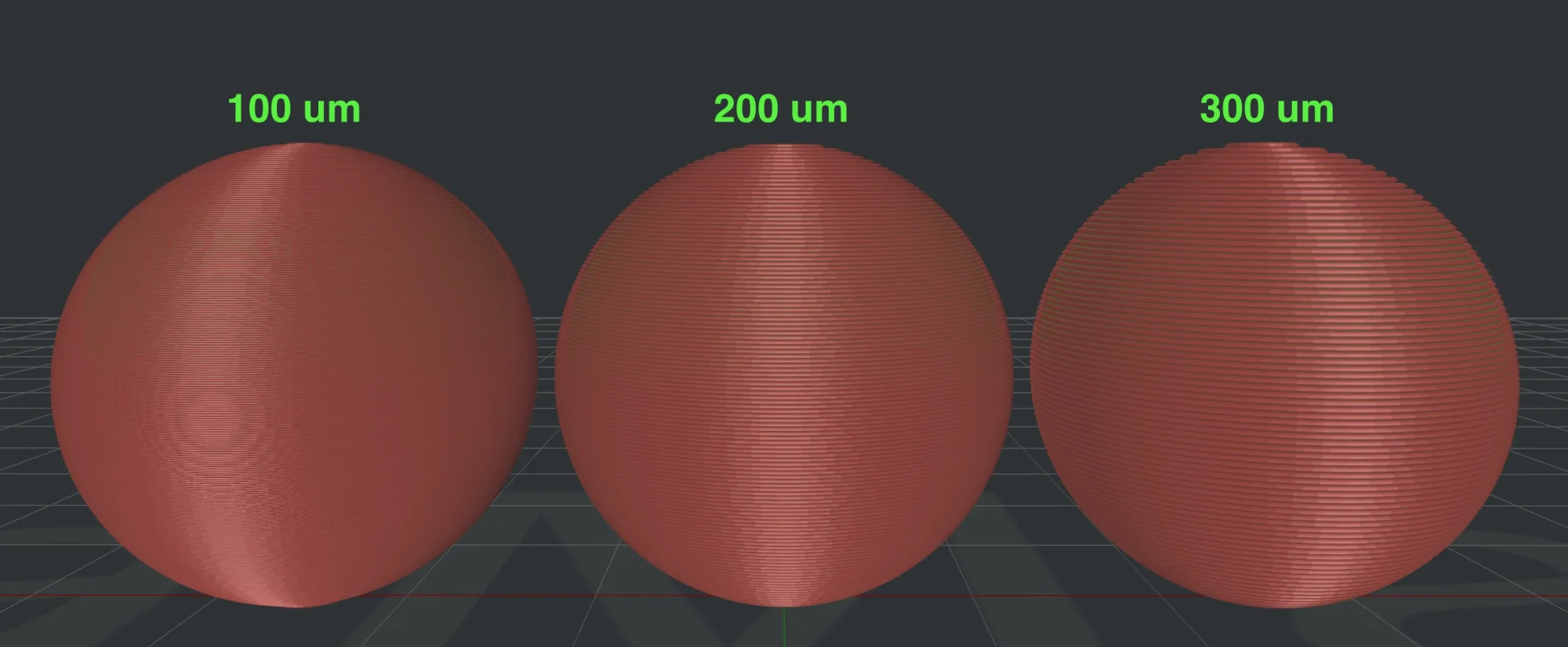

When preparing to 3D print using FDM (Fused Deposition Modeling) technology, the orientation of your 3D model can significantly impact the final cost. Here’s why it matters and how you can manage it effectively.

The Importance of Correct Orientation

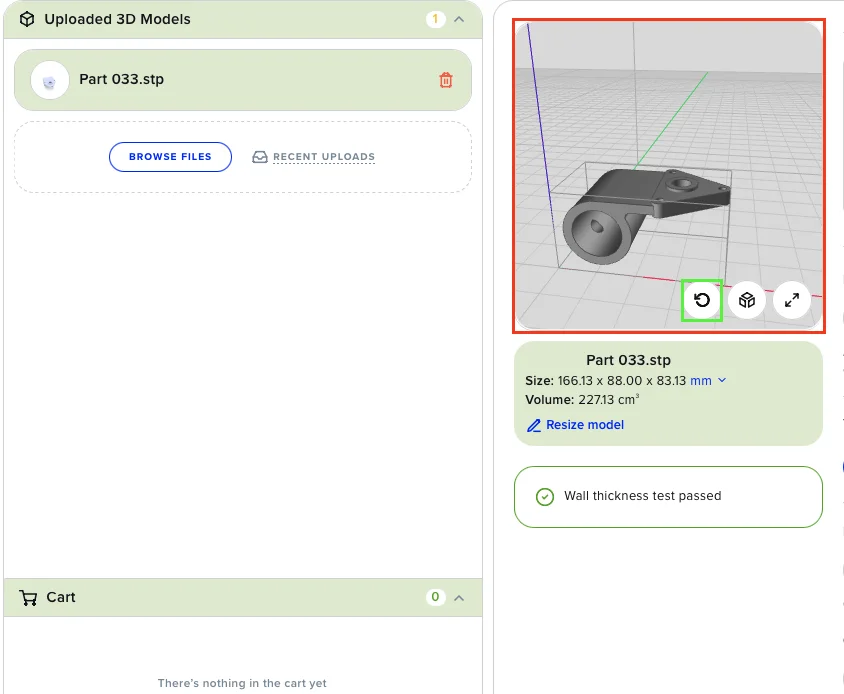

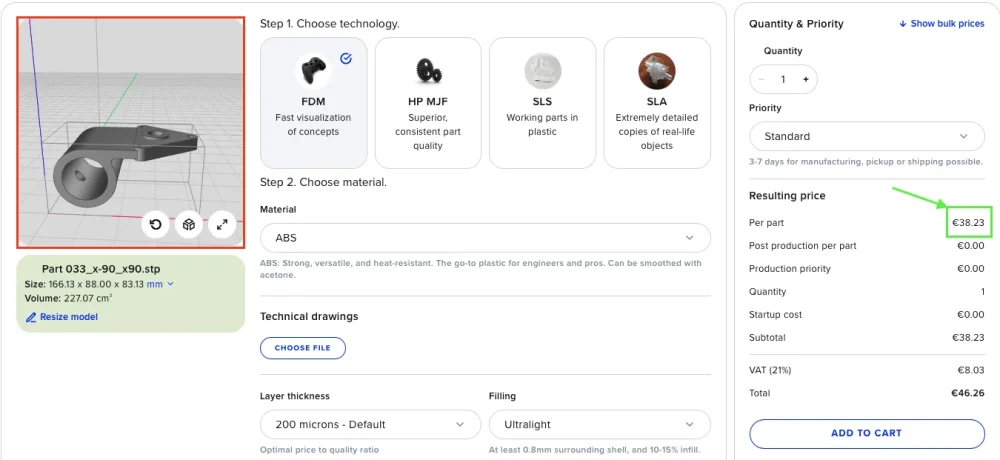

Exporting 3D models from design software like SolidWorks, Fusion 360, or Blender is a standard step if you’re aiming to 3D print an object. However, these programs handle the orientation of the Z-axis differently. Consequently, when you import your 3D model into our quotation tool, the model might not be properly aligned—it could even be upside down, calculating supports and raising the price.

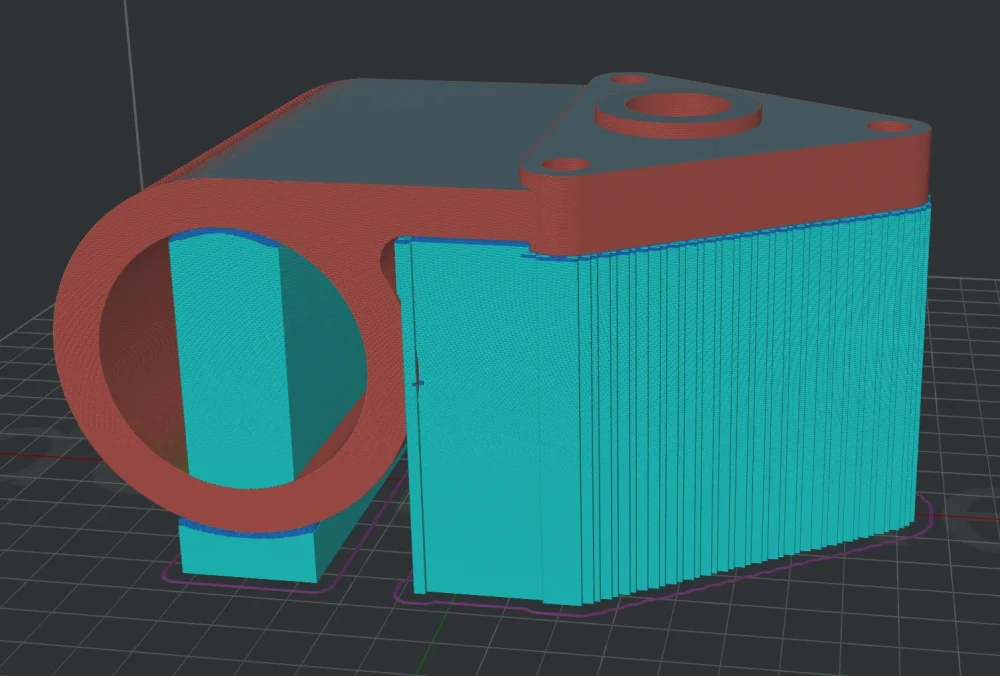

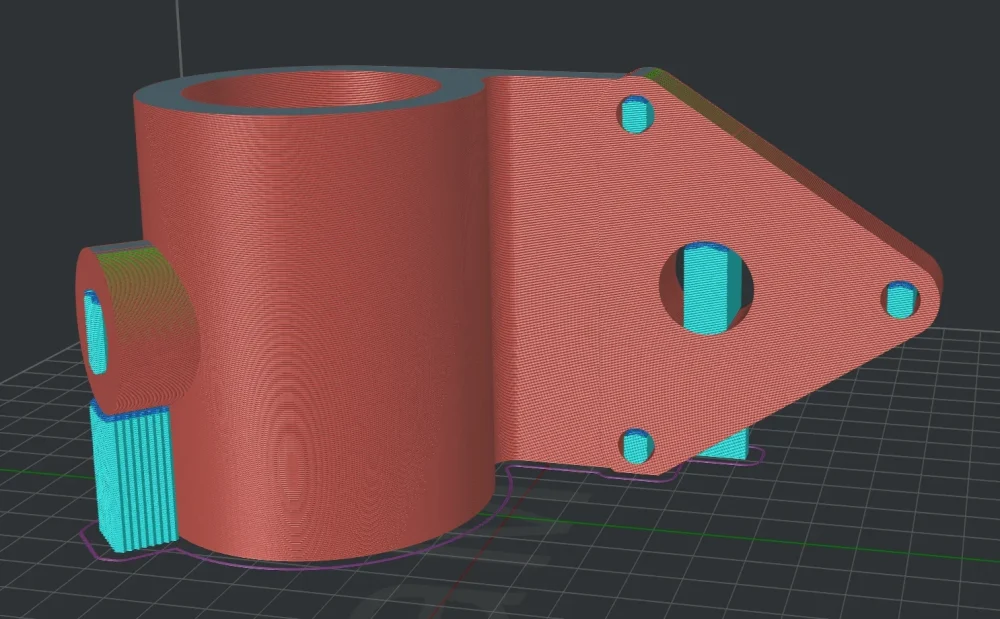

Minimizing Support Structures

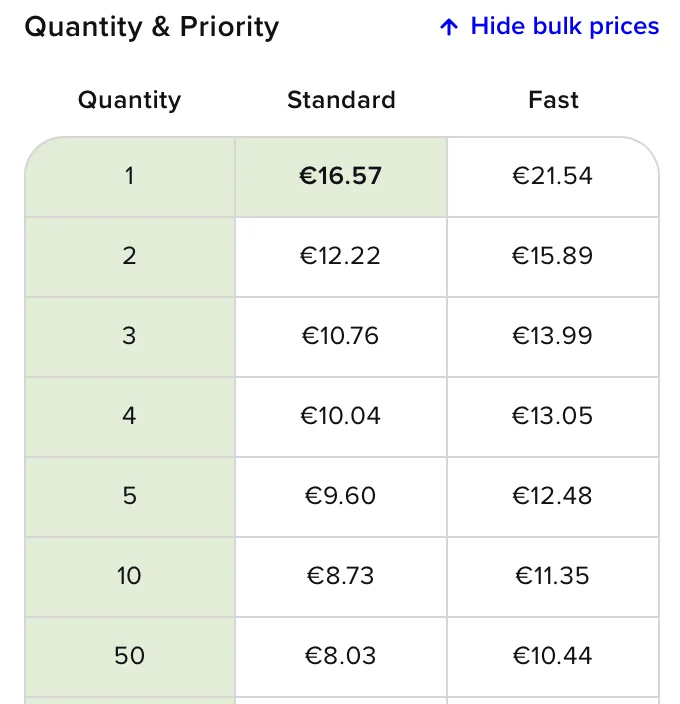

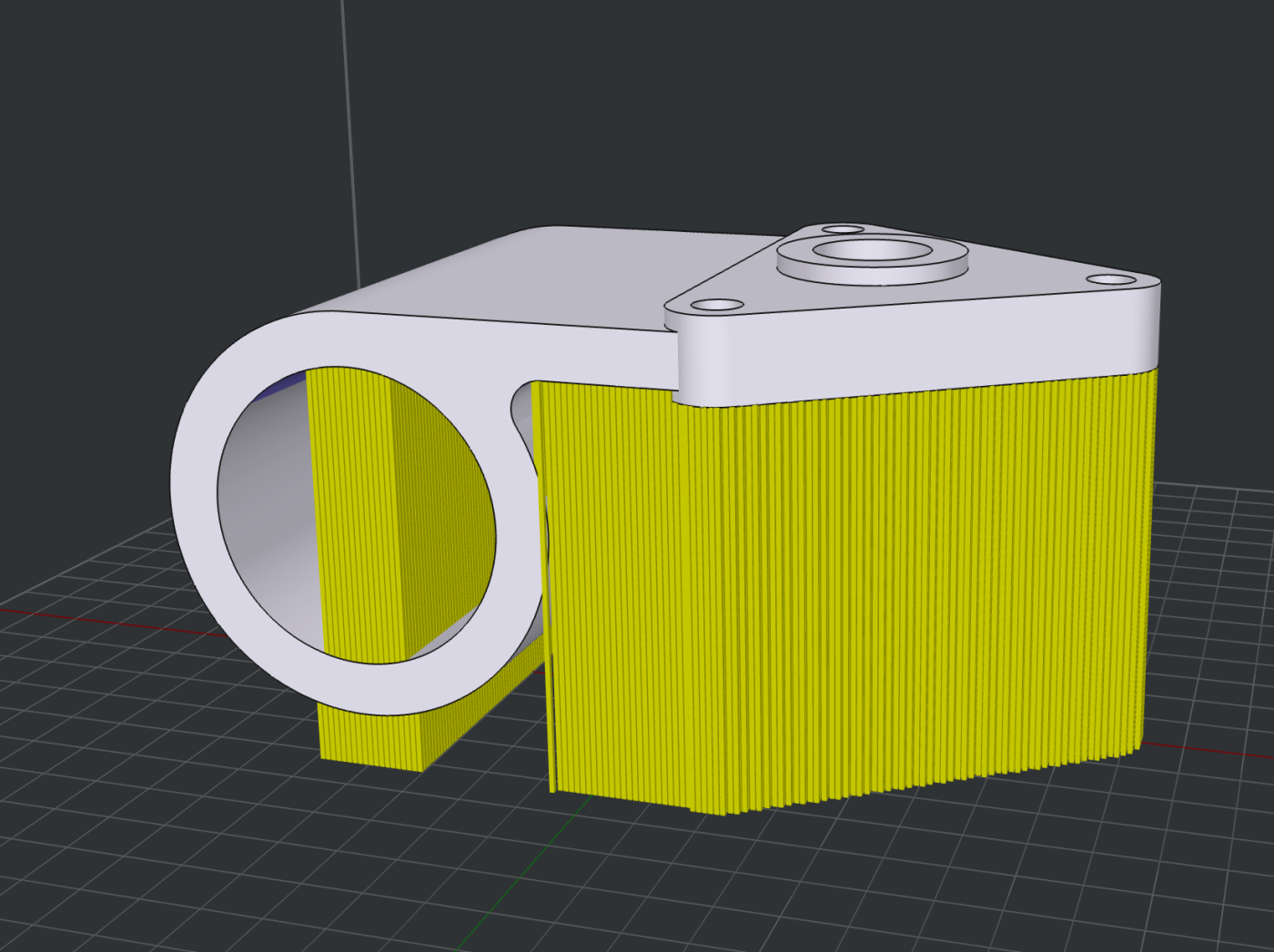

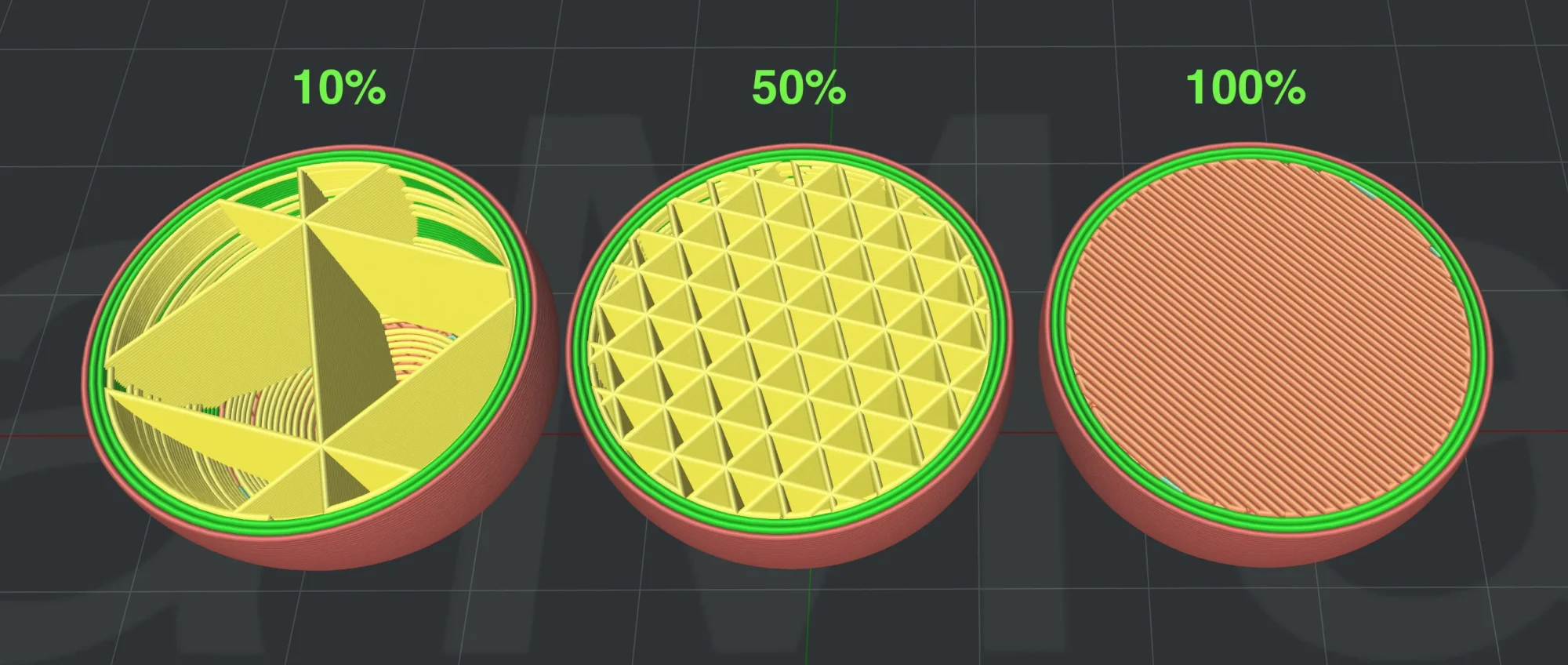

Proper orientation is crucial because it can minimize the need for support structures. Support structures add extra material, increase printing time, involve labor, and ultimately raise the cost of production. By orienting your model to require fewer supports, you can achieve significant cost savings.

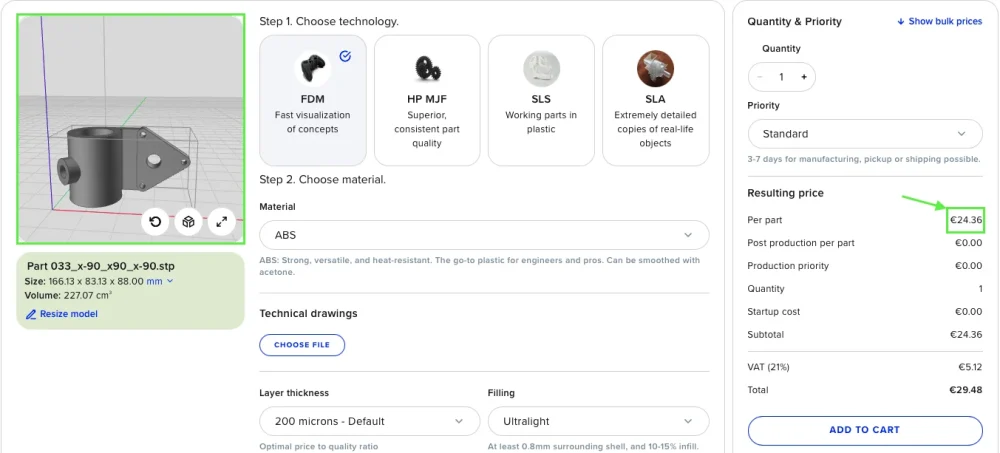

Using Our Quotation Tool

When you upload your 3D model to our quotation tool, you’ll see a preview of its current orientation. Ensure this matches your intended printing orientation to avoid unnecessary costs. Correct alignment minimizes the support needed and ensures the most efficient use of materials and time. Make sure the part is orientated well, considering the design, strength of the part, and support removal.